EFP-IL Guided UWB Radar TLI Signal Processor

Precision Tank Level Measurements for Extreme Environments

The new panel-mount EFP-IL Guided UWB Radar Signal Processor uses MOHR's 6th generation Electric Field Perturbation (EFP) technology to provide the industry's most accurate real-time liquid level and multiphase flow measurements.

With thousands of hours of operation at elevated temperatures and pressures, EFP instruments are ideal for severe environment applications.

MOHR's new panel-mount EFP-IL and portable EFP-HL TLI signal processors and SFP-1 Spent Fuel Probe form an ideal solution for the U.S. Nuclear Regulatory Commission's (NRC) EA-12-051 Order to Modify Licenses With Regard to Reliable Spent Fuel Pool Instrumentation (SFPI), issued in response to lessons learned from the Japan nuclear accident in March 2011 at Fukushima Dai-ichi.

EFP-IL TLI System Key Features

- Industry's most accurate liquid level measurements*

- Designed for severe environmental conditions

- Characterize boiling / frothing environments

- Electronics can be >300 m (1000 ft.) from the sensor probe

- In-situ real-time instrument calibration

- Inline probe signal-path integrity monitoring

- Ideal for use with MOHR SFP-1 spent fuel probe

Industry's Best Precision and Accuracy

- Unmatched signal processor precision and accuracy of approximately 0.1 mm (0.004 in.) and 1 mm (0.04 in.), respectively

- Real-world TLI system accuracy, including probe surface tension effects, better than ± 12.5 mm (0.5 in.) for most industrial applications

- Fixed (EFP-IL) or portable (EFP-HL) signal processors can be located more than 300 m (1000 ft.) from the probe with relative accuracy of ~3 mm (0.1 in.)†

Rugged Performance for Industrial Environments

- Panel-mount NEMA 4X all-weather enclosure

- Designed to meet MIL-SPEC and NRC seismic, shock, vibration, environmental, and EMC requirements

- Weatherproof MIL-DTL-5015 circular connectors for external connections

Intuitive Graphical Interface

- Informative graphical user interface reports instantaneous level in length or calibrated volume units

- Evaluate recent tank level trends with real-time level history graph, stored in flash memory

- In-depth diagnostics and password-protected system configuration simplify maintenance

Flexible Configuration Options

- Ethernet, USB host/client, 4-20 mA, HART, RS-232, 802.11 b/g/n WiFi

- Optional SPDT or DPDT level alarm relays

- Optional thermocouple, RTD signal processors

- Redundant, seamless battery backup with EFP-BAT-44000

Optional Void Fraction Measurements

- With specialized probes and firmware, the EFP-IL can provide local volumetric void fraction measurements

- Estimate total coolant enthalpy and identify nucleate boiling and other conditions influencing heat transfer

- Differentiate bubble, slug, churn, and annular flow regimes in real time

- Better local and temporal accuracy than gamma densitometry without radiation safety issues

- Accuracy to ±1%‡ void in steam-water environments with as low as 1 ms acquisition for rapid transient conditions

†Absolute and relative measurement accuracy may vary by installation and depending on severity of environmental conditions.

‡Bubbly flow; accuracy may vary depending on flow regime and environmental conditions.

MOHR SFP-1 Spent Fuel Pool Probe Assembly

The new MOHR SFP-1 Spent Fuel Pool Probe Assembly is a MIL-SPEC hardened intrusive metallic probe with support assembly qualified for installation in BWR and PWR spent fuel pools without modification to the pool liner. The SFP-1 probe components have been qualified for long life at nuclear temperatures and pressures and are constructed of radiation-resistant materials necessary for an estimated 40 year probe life. The SFP-1 probe is designed to provide accurate liquid level information even in severe accident conditions.

SFP-1 Probe Key Features

- Configurable lengths of 1.5 - 10+ m (5 - 32+ ft.)

- Exceeds Seismic Category I criteria

- Long term use at 250°C (480°F) or above

- Excellent long-term radiation resistance

- EFP-IL/HL interconnect cable >300 m (1000 ft.)

- Relative accuracy ± 3 mm (0.1 in.) at 300 m (typ.)

- Absolute accuracy ± 25 mm (1 in.) at 300 m (est.)

- Compatible with EFP-IL and EFP-HL signal processor in-situ calibration

What is EFP Technology?

Using specialized metallic probes as waveguides, EFP (Electric Field Perturbation) Series signal processors use ultra-wideband signals that propagate in a process similar to radar. The resultant complex backscatter allows for the determination of liquid level and multiphase flow characteristics such as void fraction.

EFP technology addresses weaknesses inherent in legacy guided-radar / TDR liquid level instrumentation, providing enhanced accuracy and confident level measurements even in boiling / frothing environments.

EFP-IL Guided UWB Radar TLI Signal Processor, 1-channel configuration.

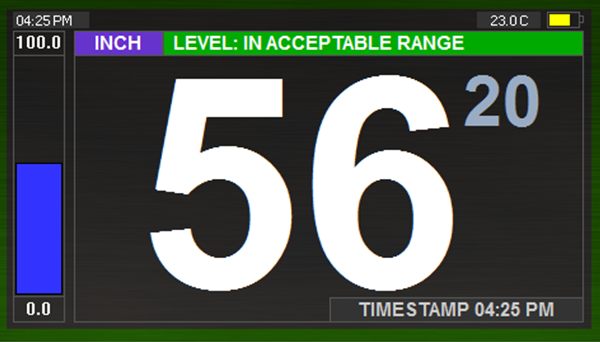

EFP-IL numeric water level display with real-time TLI system health check indicators. Green border and indicators indicate normal system operation.

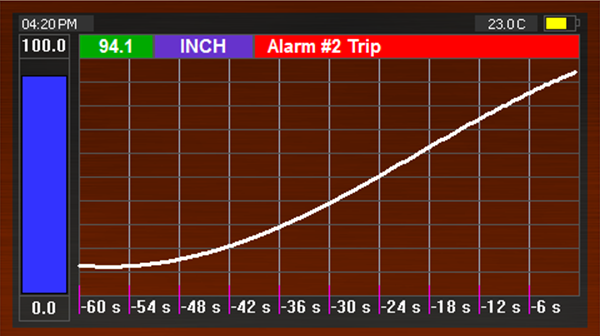

EFP-IL real-time water level time history plot with level alarms. The red border and warning message indicates that the upper level alarm has been tripped.

Mechanical

EFP-IL Signal Processor:

30.5(H) x 25.4(W) x 21.0(L) cm

(12.0 x 10.0 x 8.3 in.)

12.7 kg (27.9 lbs.)

Panel/Wall or Unistrut P1000 mounting

EFP-BAT-44000 External Battery Enclosure:

30.5(H) x 35.6(W) x 16.0(L) cm

(12.0 x 14.0 x 6.3 in.)

18.9 kg (41.6 lbs.)

Panel/Wall or Unistrut P1000 mounting

Environmental

Operating Temperature: -10°C to +55°C

Non-operating Temperature: -20°C to +85°C

Regulatory

SFPI Version (EFP-IL and EFP-BAT-44000):

Tested to meet the following standards:

IEEE 344:2004 Seismic (14.0 g SSE, 9.8 g OBE)

IEC 60068-2-27 Shock

IEC 60068-6-8 Vibration

EPRI TR-102323-R3 EMC

Naval Version (EFP-IL only):

Designed to meet applicable sections of the following standards:

MIL-STD-108 Environmental

MIL-S-901D Shock (High Impact)

MIL-STD-167-1 Vibration

MIL-STD-461F EMC

MIL-STD-810G 509 Salt Fog

MIL-STD-810G 511.5 Explosive Atmospheres

Designed to meet relevant requirements for Naval shipboard liquid level indicating equipment per MIL-L-23886C and ASTM F 2044-00.

Complies with all applicable EU directives, as specified by the Declaration of Conformity supplied with the instrument.

Complies with Canadian ICES-003.

Datasheet

![]() EFP-IL Datasheet (11/23/13).

EFP-IL Datasheet (11/23/13).

How to purchase

Please contact us for more information.