MOHR EFP-IL SFPI System — Spent Fuel Pool Level Instrumentation (SFPI)

The MOHR EFP-IL SPFI System offers rugged, reliable, accurate water level and temperature measurement qualified for the nuclear spent fuel pool environment and superior to other vendors' offerings*:

- The EFP-IL SFPI System meets all NRC Order EA-12-051, NEI 12-02, and JLD-ISG-2012-03 requirements for reliable spent fuel pool water level instrumentation (SFPI).

- 47+ channels of EFP-IL SPFI hardware being supplied to 21+ U.S. and international NPPs.

- Avoid problems routing rigid waveguides, EMI/RFI problems, distance limitations, poor accuracy, heavy stilling wells, and problems with debris that can block Through-Air radars and adversely affect legacy Guided-Wave Radar (GWR).

- MOHR has been manufacturing enhanced GWR / TDR water level instrumentation for more than 30 years. Equipment is purchased direct from the manufacturer (MOHR) without retail markup.

Introducing the MOHR EFP-IL SFPI System

- The EFP-IL SFPI System uses enhanced UWB GWR / TDR technology originally developed for U.S. Navy applications.

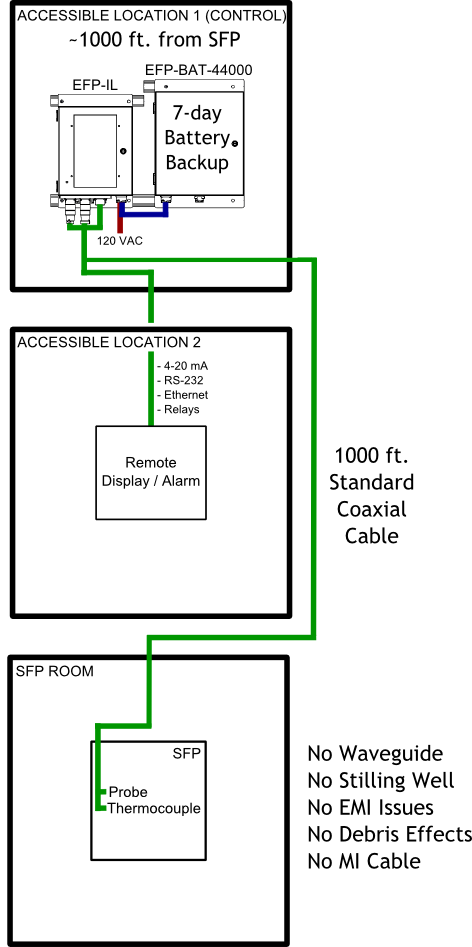

- The System includes the EFP-IL Signal Processor, EFP-BAT Battery Enclosure, and SFP-1 Level Probe Assembly.

- The EFP-IL Signal Processor connects to SFP-1 probe through standard LOCA-rated coaxial transmission cable up to 1,000 ft. (300 m.) length.

- Accurate liquid level measurements regardless of presence of debris, boiling, or boric acid.

- Rugged SFP-1 water level probe designed for Category 1 seismic and hydrodynamic loading.

- Low-power operation with integrated compact battery backup adequate for at least 7 days.

Advantages of the MOHR EFP-IL SFPI System

- Industry's most accurate GWR water level measurements*.

- Reliable measurements with boiling, boric acid, and in the presence of debris that can block Through-Air radars and adversely affect legacy GWRs.

- In-situ real-time instrument calibration and inline monitoring of cable and probe health status.

- Continuous data-logging of water level, temperature (K-type thermocouple or 2-4 wire RTD), system status.

- Diverse telemetry options including 4-20 mA, RS-232 Serial, Ethernet†.

- Accepts external DC power sources for fail-safe operation (external DC supply, automotive battery, etc.).

- Similar cost to competing Through-Air and Guided-Wave radar solutions with better performance.

Quality and References

- Manufacturing compliant with the stringent AS9100C aerospace quality standard.

- Augmented Quality meeting NRC Order EA-12-051, NEI 12-02, and JLD-ISG-2102-03 requirements for SFPI.

- Tested to meet IEEE 344:2004 (seismic), EPRI TR-102323-R3 (EMC), and NEI 12-02 requirements for shock/vibration, temperature/humidity, power reliability.

- 47+ channels supplied to 21+ U.S. and international nuclear plants including Utilities Service Alliance (USA) Member Stations.

Comparison of MOHR EFP Technology with

|

|||

|---|---|---|---|

| MOHR EFP-IL SFPI System UWB Guided-Wave Radar |

Through-Air Radar | Legacy Guided-Wave Radar |

|

| Operation | UWB radar pulses reflect off water surface; time delay and frequency/phase information used to determine and refine water level measurement. | Radar pulses reflect off water surface; time delay used to determine water level measurement. | Radar pulses reflect off water surface; time delay used to determine water level measurement. |

| Distance Limitations | 1,000 ft. of standard commercial coaxial cable places electronics far from heat and radiation of SFP area. Can be installed anywhere, with or without additional protection of conduit, trenches, or cable trays. | Rigid waveguide suspended over pool limited to 212 ft.* can make installation challenging. Installed directly in the path of falling and wind or explosion-driven debris. Mechanical deformation of the waveguide or antenna distorts radar propagation. | Variable, discuss with vendor. Typically limited distance with poor accuracy with longer transmission cable lengths. |

| Accuracy | Approximately 1 in. through 1,000 ft. of transmission cable (typ.). | Unknown. Ask vendor what accuracy is through maximum length of waveguide. | Unknown. Ask vendor what accuracy is through maximum length of transmission cable. |

| Simplicity | Electronics, flexible coaxial cable (standard coax on spool, cut to length in the field), probe. | Electronics, rigid waveguide pipe (custom manufactured), horn antenna suspended above pool in path of falling and wind or explosion-driven debris. | Variable, typically electronics, flexible coaxial cable, probe. May require stilling well or MI cable. |

| Installation | Standard flexible commercial coaxial cable is easy to route. No need for mineral-insulated cable. Lightweight probe and simple SFP deck bracket. No stilling well. | Rigid waveguide can be challenging to design and route to fit in existing plant structure. Limited distance to electronics can present additional design and installation challenges. | Variable distance limitation can be challenging regarding placement of electronics. May require mineral insulated cable which is challenging to route. May require stilling well, which can complicate pool bracket design due to added weight and seismic/ hydrodynamic loading. |

| Debris | Debris have no measurement effect. Probe is inherently rugged and protected from debris by pool corner walls. | Large debris (e.g. falling roof material) above the water level may introduce a false reading. Damage to the exposed horn antenna and rigid waveguide from falling and wind or explosion-driven debris may render the system inoperable. | Debris contacting the signal wire above the water level may introduce a false reading if stilling well is not used. |

| Event Survivability | Robust military-grade design. Electronics qualified to 14 g RRS. Probe qualified to at least 5.4 g. Due to robust probe and transmission cable, protection of hardware in the pool corner, and remote electronics, damage to the SFPI system is very unlikely. | Installed above the pool, not subject to hydrodynamic loading but subject to falling and wind or explosion-driven debris; beyond-design-basis seismic damage to supporting plant structure may render the exposed waveguide or antenna inoperable. | Variable, typically protected in the pool corner, flexible designs unlikely to be damaged by seismic/hydrodynamic interaction however interaction with debris above the water level could impair accuracy or render system inoperable. |

| Maintenance | In-situ calibration without moving the probe. Low maintenance costs and available service contracts. | In-situ calibration may require repositioning the horn antenna. Low maintenance costs. Ask about cost of service contracts. | In-situ calibration requirements vary but may require moving the probe. Stilling well may complication calibration. Low maintenance costs. Ask about cost of service contracts. |

| Cost/Value | Equipment direct from equipment manufacturer (MOHR) without retail markup. | Vendor is an equipment reseller with substantial retail markup. | Vendor is an equipment reseller with substantial retail markup. |

† Depending on instrument configuration and selected options.

How to Purchase

Please contact us for more information.